R&D Center

Take a Brake!

Appearance May be Imitated,

but Sangsin's Cutting-edge Technology Cannot be Imitated.

Each of our products is a critical part that affects our client’s lives.

Hence, Sangsin only supplies 100% perfect products,

allowing for zero defects throughout the entire production process.

Testing Equipment

-

Chassis Noise Brake Dynamometer

- Realizing actual driving and braking conditions with a real car.

- Controlling environmental conditions(temperature/humidity).

- Anechoic chamber.

- Analyzing brake NVH (Noise, Vibration, Harshness) test.

-

Performance Dynamometer

- Realizing the brake system for driving and braking in each of the brake module: a ¼ car, and a ½ car unit.

- Evaluating the brake performance, abrasion, and NVH tests of the brake system.

- Controlling environmental conditions (temperature/humidity).

-

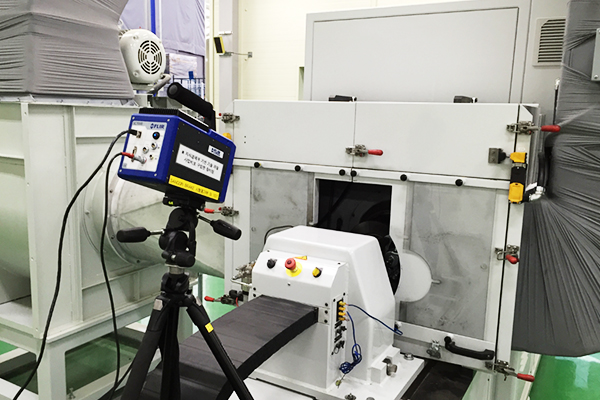

Thermographic Camera

- Analyzing the thermal behavior of the disc at braking.

- Able to measure the temperature of a high-speed rotating disc.

- Analyzing the distribution of temperature for noncontact types.

-

Multichannel Analyzer (DAQ)

- Measuring and analyzing NVH (Noise, Vibration, Harshness).

- Modal Analysis, ODS (Operational Deflection Shape), Frequency Analysis etc.

-

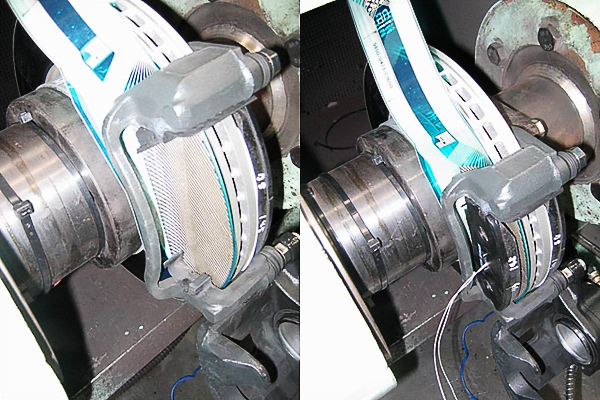

Measurement of the Surface Pressure of Friction Materials

- Analyzing the distribution of contact stresses between the disc and the brake pad.

-

Real car performance DAQ

- Attached to the real car for brake related testing.

- System for collecting and analyzing brake performance and NVH data.

Analysis Equipment

-

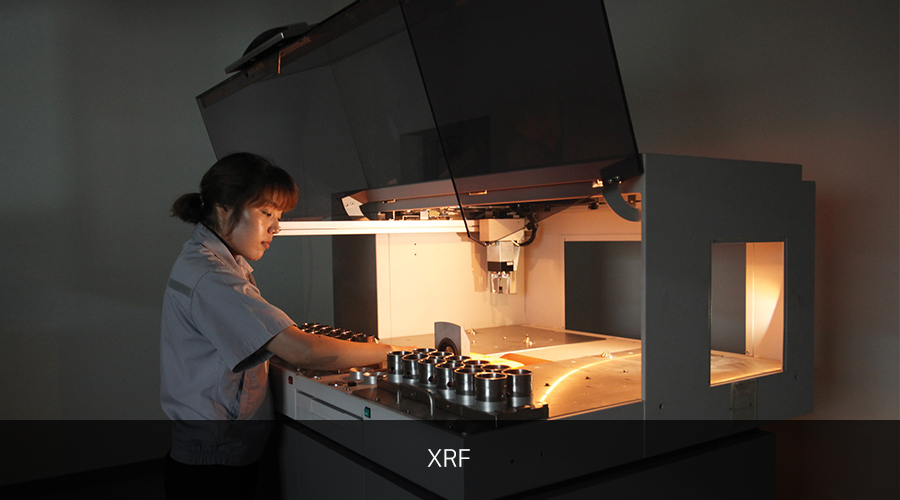

XRF (X-Ray Fluorescence Analyzer)

- Qualitative analysis of inorganic matters of friction materials and raw materials.

- Identifying the quality dispersion of friction materials and the homogeneity through qualitative and semi quantitative analysis.

-

SEM/EDS(Scanning electron microscopy/energy dispersive x-ray spectroscopy)

- Observing and analyzing raw material components and compositions.

- Benchmarking of competitors’ products through observing and analyzing components.

-

Cyclic Corrosion Test Chamber

- Testing the severity of corrosion attack to the product in accordance with the environmental conditions (saltwater, temperature, and humidity).

-

DMA

- Analyzing the damping characteristics of friction materials in accordance with temperature and vibration conditions.

-

PSA (Particle Size Analyzer)

- Measuring particle sizes of raw materials in less than 2,000 ㎛.

-

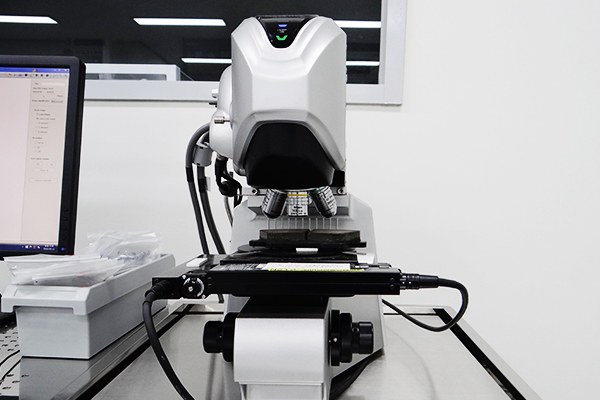

Confocal Microscopy

- Investigating the distribution of plateaus on the friction material surface and the correlation between noise and vibration.

- Analyzing the uniformity of the pressure on the surface based on the friction contact area shape.

- Analyzing the abrasive particle shape of testing and identifying the wear-factor parameter.

한국어

한국어 english

english 中文

中文 español

español Português

Português